DOJO

PRODUCTION

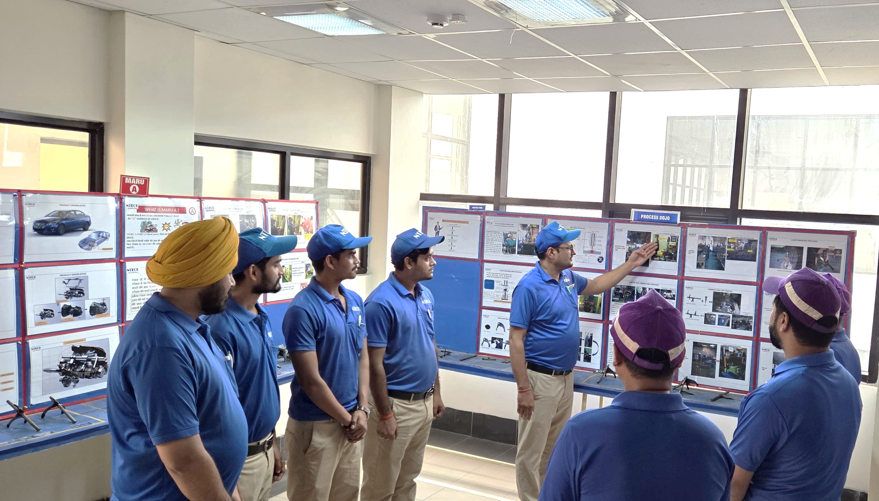

At NTECK Automotive, excellence isn’t just built—it’s trained. Our Production Dojo is a dynamic learning environment where precision, performance, and deep product knowledge come together to create automotive brilliance. Whether you’re stepping onto the floor for the first time or returning to sharpen your expertise, this is where every part finds its purpose—and every teammate finds their

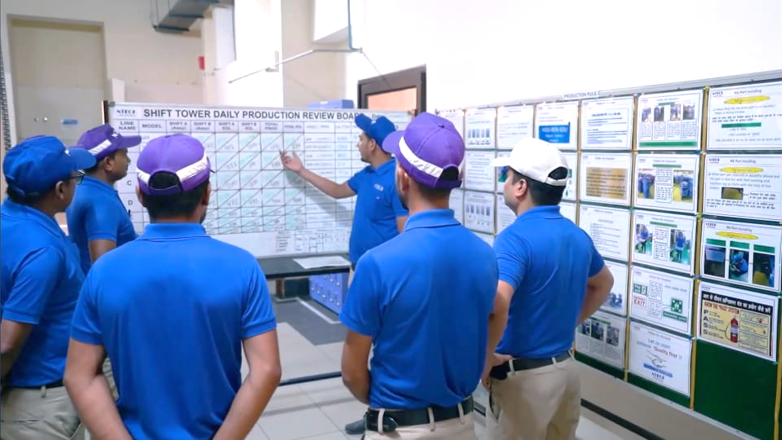

PRODUCTION RULE

At Nteck Automotive, the Production Rule Dojo is where discipline meets precision. In this purpose-built zone, we cultivate a culture of excellence by training every team member—new joiners and seasoned experts alike—in the core rules that drive our manufacturing success. Through immersive modules, visual SOPs, and hands-on simulations, we reinforce standardized practices, eliminate process variation, and strengthen our collective commitment to safety, quality, and continuous improvement. This is not just training—it’s the foundation of world-class craftsmanship

QUALITY

At Nteck Automotive, the Quality Dojo is where precision is perfected. Designed as an immersive space for mastering measurement instruments and inspection protocols, this dojo empowers every team member with the knowledge to uphold the highest standards of quality. From calipers to micrometers and height gauges, each tool is introduced with hands-on experience and backed by real-world application facts. New joiners and experienced inspectors alike refine their expertise through guided modules, practical simulations, and evaluation drills—ensuring that every product that leaves our floor meets global benchmarks of excellence

COMPANY OVERVIEW

At NTECK Automotive, the Company Overview Dojo is where purpose meets clarity. This dedicated orientation space serves as a launchpad for new joiners and a refresher for existing staff, immersing them in the company’s history, vision, values, and guiding principles. Through interactive sessions, storytelling modules, and policy walkthroughs, team members gain a deep understanding of what NTECK stands for—from its origins and innovations to its cultural DNA and business ethics. In this dojo, knowledge isn’t just shared—it’s instilled, creating a workforce that’s aligned, inspired, and ready to build the future of mobility.

SAFETY

At NTECK Automotive, safety is an essential part of our Dojo culture, where learning and collaboration thrive in a secure environment. As part of joining the team, new members are guided through a safety orientation led by our Safety Officer, introducing the use of protective equipment, safe handling practices, emergency awareness, and respectful care of shared spaces. This shared understanding helps us look out for one another and maintain a safe, supportive space where everyone can grow with confidence.

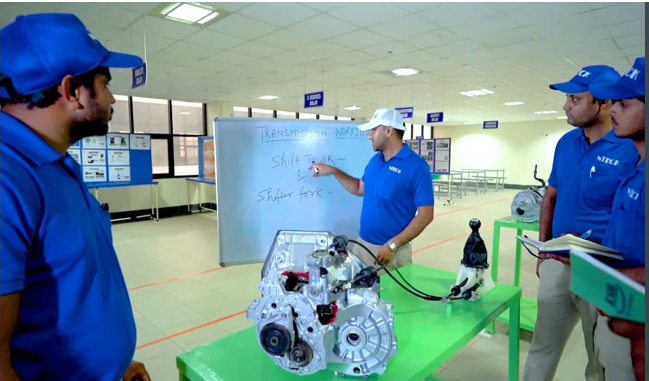

EDUCATION

At NTECK Automotive, the Dojo area is a special learning space where our team gets practical training in Japanese technology, innovation, and lean management. With guidance from senior managers trained in Japanese methods, we focus on hands-on education, skill-building, and continuous improvement to grow technical knowledge and teamwork.

At NTECK Automotive, our Dojo area is a hands-on learning hub where employees are trained in Japanese technology, innovation, and lean management. Guided by senior managers with direct experience in Japanese practices, we focus on continuous improvement and technical excellence

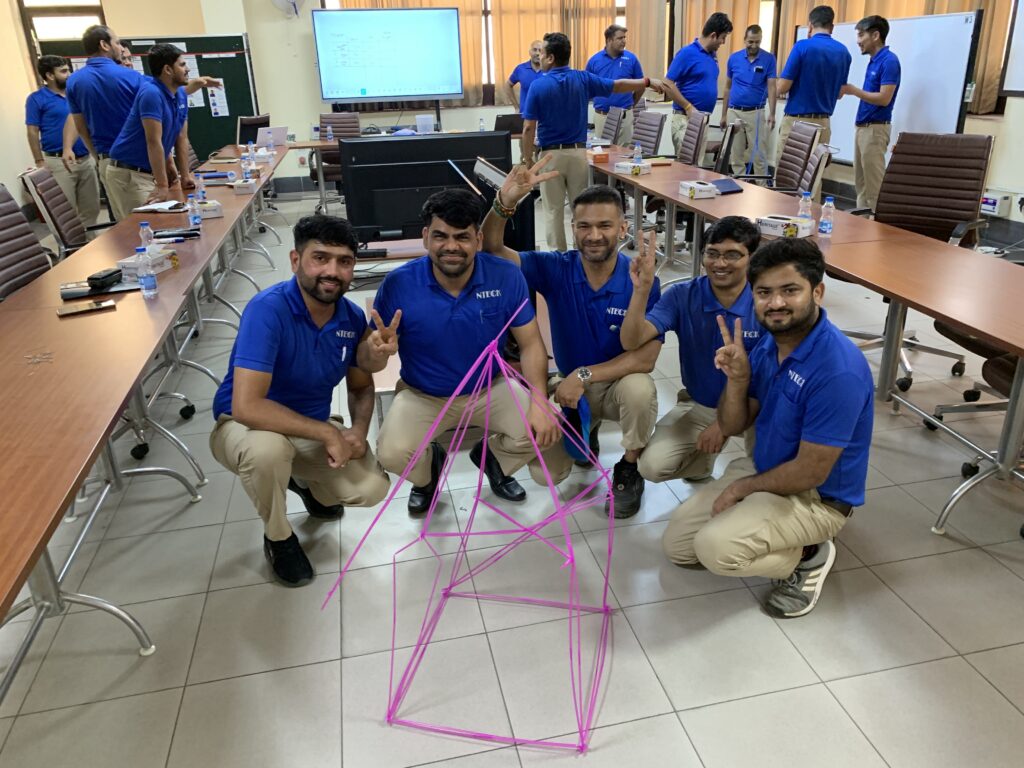

LEARNING AND DEVELOPMENT

At NTECK Automotive, staff training is deeply rooted in the principles of Japanese management, emphasizing continuous improvement (Kaizen), workplace discipline (5S), and experiential learning (Gemba). The program aims to develop technical proficiency, foster teamwork, and instil a mindset of accountability through structured modules and on-the-job coaching. By blending practical skill-building with behavioural development, employees evolve into agile, quality-focused professionals who embody NTECK’S commitment to excellence and innovation.

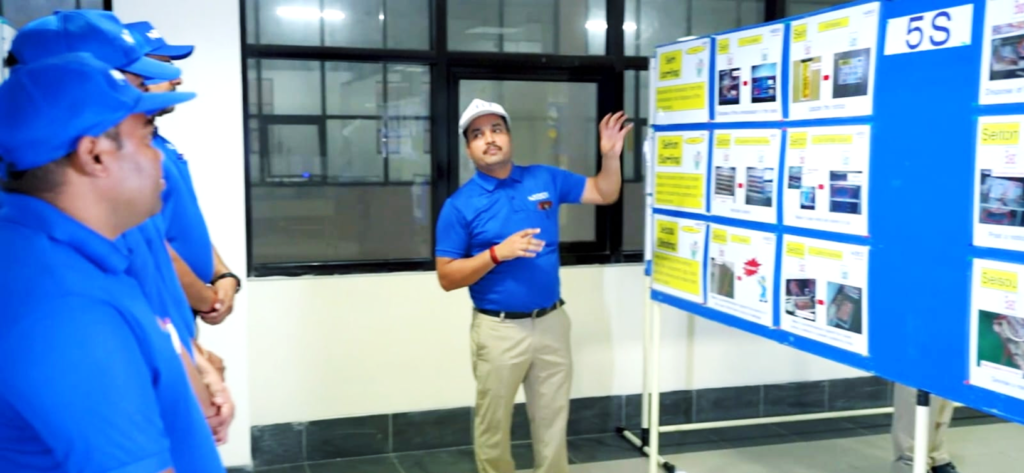

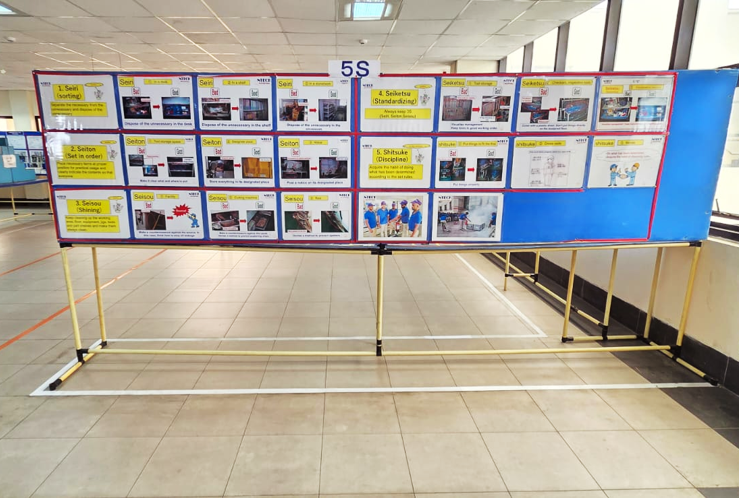

5S TRAINING

At Nteck Automotive, 5S training is a fundamental part of our Dojo culture, rooted in traditional Japanese management practices. The 5S principles—Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—are introduced to all new joiners to build habits of cleanliness, efficiency, and discipline. Through hands-on learning in the Dojo area, team members gain practical skills that support a safe, organized, and continuously improving workplace.